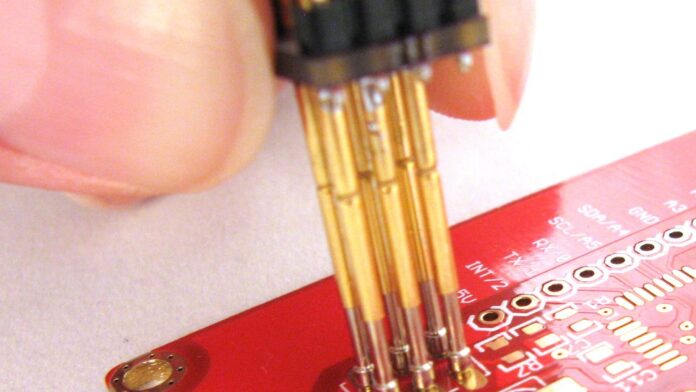

If you have a background in electrical engineering or have been to an electrical workshop, you would know what pogo pins are. However, for those who have yet to figure it out, pogo pins are electrical connectors designed to make temporary connections between two conductive surfaces. They are very close in function to traditional connectors such as plugs and connectors, but their specialty lies n their design. They are designed to be more compact, durable, and reliable.

Pogo pins are also known as spring-loaded pins. The name “pogo pin” comes from the fact that they “jump” or “spring” into place when they are brought into contact with a conductive surface. Thanks to their versatility and durability, Pogo pins have become increasingly popular in recent years and are used in various applications.

In this blog, we will look at the major types of Pogo pins and explain these electrical devices’ noteworthy applications.

What Are the Types Of Pogo Pins?

Though there might be several other categorizations of these electrical devices, the two most common types of pogo pin connections are:

- Normal open (NO) contacts are typically closed when the connector is in use.

- Normal close (NC) contacts are typically open when the connector is in use.

Pogo pins can connect various conductive surfaces, including metal, metal-coated surfaces, and even conductive rubber or plastic. They can connect PCBs, PCBs, and other components, and even between two PCBs.

Applications of Pogo Pins

Pogo pins are used in a wide variety of applications, including:

PCB Testing:

Pogo pins are commonly used in the automated testing of PCBs. They can connect a test fixture and a PCB, allowing automated test equipment to test the various components on the PCB.

Medical Equipment:

Pogo pins are often used in medical equipment, such as electrocardiogram (ECG) machines, to connect patient leads and the machine. They are durable and can withstand repeated use, which is important in medical applications where the equipment is used often.

Robotics:

Pogo pins are also used in robotics applications to connect robots and other equipment. They are particularly useful in robotic arms, where a small, durable connector is needed to connect the robot’s control electronics and various motors and sensors.

Industrial Equipment:

Pogo pins are used in many types of industrial equipment, such as control systems and industrial robots, to make connections between various components. They are particularly useful in harsh environments, where traditional connectors may fail due to vibration, dust, or other factors.

Mobile devices

Pogo pins are also commonly used in mobile devices, such as smartphones and tablets, to connect the device’s battery and control electronics. They are small, durable, and reliable, making them an excellent choice for mobile devices.

Conclusion

Pogo pins are versatile and reliable connectors that are used in a wide variety of applications. They are particularly useful in harsh environments, where traditional connectors may fail. They are more durable than traditional connectors, and their spring-loaded mechanism allows for a secure and stable connection. They are also great for mobile devices and automated testing, where a small, durable connector is needed.