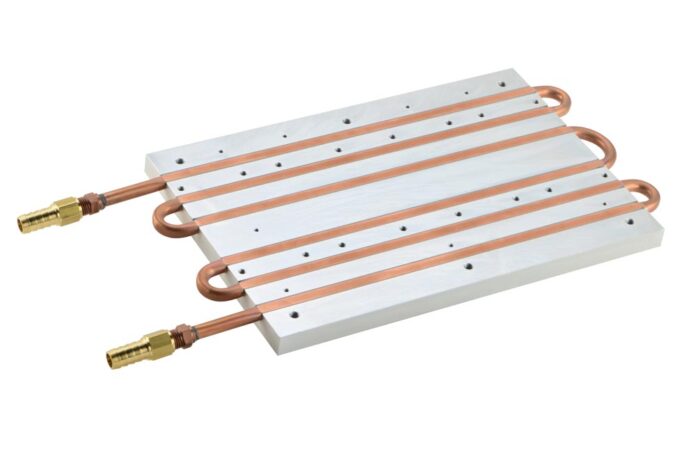

Components dissipate heat while operating. Therefore, they require a medium to remove the excessive heat as it negatively impacts their performance and lifespan. Such mediums which keep the electrical components running at an optimal temperature are called heat sinks.

Heat sinks fall into two categories: Air-cooled and liquid-cooled heat sinks. Initially, air-cooled heat sinks were sufficient to keep the components at an optimal temperature. However, as components became more high-performing and generated more heat, a liquid cooled heat sink became necessary. Let’s examine why water-cooled heat sinks dominate air-cooled heat sinks.

Water Cooled Heat Sink Vs. Air Cooled Heat Sink

Many people remain confused about the applications of heat sinks. However, they are present everywhere where there are components. Heat sinks exist in computers, transportation systems, electronic chips, and other sectors with powerful electric elements.

The Cooling Substance

The first thing that distinguishes water-cooled heat sinks from air-cooled liquid heat sinks is the cooling material. As the name specifies, air-cooled heat sinks use air for cooling, while water-cooled heat sinks use water to absorb the heat.

It is important to note that water-cooled heat sinks are liquid-cooled heat sinks. I.e., the heat sinks that use coolants.

Absorption Rates

Water-cooled heat sinks have a higher absorption rate and therefore remove the heat quickly compared to air-cooled ones. Studies show that water-cooled heat sinks absorb heat 10 to 15% faster.

Water can absorb large amounts of heat easily. Therefore, it prevents rapid temperature rises in the components even during heavier tasks.

In contrast, the air has a low heat capacity and tends to get hot quickly. Therefore, you need a high-speed fan, so cold air can enter the system quickly, which creates more noise.

Noise Reduction

Water-cooled heat sinks use heat exchangers to exit the heat from the water tubes. It reduces the noise as there is no need to use high-speed fans. Although the water pump generates some noise, it is not very noticeable.

Compactness

Next comes compactness. Air-cooled systems require more space as heavier systems need more cooling and, ultimately, a larger fan. Also, you have to be extra careful about the placement. If the ventilation ports are blocked or are opposite to the airflow, the cooling will not be effective. Water-cooled systems occupy less space as they don’t need big fans and specific placements.

Accessibility

Water-cooled heat sinks are readily available in the market as they primarily exist in modern-day devices. Their popularity has also reduced their costs; if you need a replacement, it is readily available.

In comparison, air-cooled heat sinks are not very common these days and therefore are hard to come by. However, they are available with some sellers.

Conclusion

Heat sinks have two main categories, air-cooled and liquid-cooled heat sinks. Water-cooled heat sinks are the most common type of liquid-cooled heat sinks. They provide remarkable performance, occupy less space, work efficiently, and have no placement limitations. But they do have some downsides as well.

For instance, they require environmental seals to keep from leaking. If there is a leak, it can damage the active component. Moreover, they are pricier than air-cooled heat sinks. In the long run, they have more pros than cons. Therefore, most users prefer them nowadays.